447

Views & Citations10

Likes & Shares

- External Wearable Devices, such as Hearing Aids, Prosthetics and Dental Products

- Clinical Study Devices for Drug Testing, Patient-specific Organ models and Tissue Engineering Applications

- Implants, such as Surgical Guides, Cranio-maxillofacial Implants and Orthopedic Implants

The applications of 3D Printers in healthcare further grew to prominence during the COVID-19 Pandemic. One successful story, funded by the National Science Foundation and USDA Rural Development, utilized 3D Printers to manufacture medical equipment that were in dire shortage in rural communities during the health crisis [10]. The grant funded project highlights the advantages 3D printers can have in supporting rural health systems by being able to innovatively create viable products in a short amount of time. After getting approval to start, the head of the project, Eric Wooldridge, was able to create a viable prototype in a matter of hours and make the state requested design changes in less than 20 min [10]. In essence, Wooldridge was able to make a successful impact on Kentucky’s rural healthcare system in less than 24 hours after initiating his proposal, when the healthcare system most needed it. The application of 3D printers in the medical industry is on the verge of exploding both domestically and internationally. Precedence Research reports that the industry is estimated to increase by 428% by the year 2030; with a compounded annual growth rate of 17.54%. The same study by Precedence Research found that of the 1.45 billion dollars in sales revenue in 2021, 43% of the revenue share came from the United States. By synthesizing the economic forecasting data above, we can estimate that the market value of the United States' 3D printing for the medical industry to be approximately $2.67 Billion by 2030 [11]. Due to the numerous health services that 3D printers can be incorporated into, it is necessary to narrow the scope of this research proposal to evaluate its applications to a single service [12]. Narrowing the scope of the research proposal allows researchers to conduct a more successful and detailed study on the specific applications of 3D technology within the chosen health service. In doing so, the research team can gather specific data, analyze it thoroughly, and draw meaningful conclusions about the benefits and limitations of utilizing 3D printers with that particular service or department [13]. With consideration to these assumptions, the service under scrutiny in this research proposal is the transportation and treatment of orthopedic fractures in rural health systems. Specifically, can 3D printers and Portable X-Ray Machines be viably used in rural health communities in the diagnosis, transportation and treatment of simple orthopedic fractures, with at least the same standard of care as normal procedure?

PROBLEM STATEMENT

Beginning with incidence, studies show that the number of traumatic bone fractures is on the rise in the United States; and that this is primarily due to a rise in automobile accidents, an aging population, and a younger generation that is more risk adverse [14]. Seniors are particularly at a high risk of orthopedic fractures as they fall an average of two times a year; and account for nearly a quarter of rural America’s population [15]. Seniors are projected to head over 40% of all rural households by 2030 [16]. Considering that additional studies report rural populations generally engage in riskier behavior than urban counterparts, and that injury rates increase with rurality, it is safe to assume that rural populations are more likely to experience traumatic bone fractures than their urban counterparts; and that the rate of incidence is likely to continue to rise [17,18]. From an economic perspective, a study conducted by the Right Care Alliance Patient Council reports the largest concern amongst Americans, is the cost of care and their ability to afford it [7]. Prior to the Pandemic, the American College of Healthcare Executives’ annual survey that identifies the largest issues confronting hospitals, ranked financial issues as their biggest challenge for 15 consecutive years. The biggest concern within the financial challenge section of 2021 is the increasing cost of care for financial responsibilities, such as staff, supplies and equipment. Rural healthcare executives who have limited resources and are experiencing these constraints should be actively looking for innovative technologies that can help support operations while meeting the demand of the community. As discussed in the Findings and Analysis Section, 3D Printers deserve consideration, as the preceding studies show promising signs of supporting hospital operations, while adhering to the objectives of Triple Aim [8].

PURPOSE OF THE STUDY

The purpose of this study is to investigate the applications of 3D Printers and their ability to enhance efficiency in delivering rural health services. This research question leads to the proposal’s hypothesis that if Portable X Ray Machines are used in the diagnosis of orthopedic fractures in rural health systems, and 3D Printers are used to manufacture casts during long distance patient transportation, then the availability of beds in rural health systems will increase, as organizations meet the objectives of Triple Aim. By embarking on this study, researchers are looking for concrete opportunities to diversify both the American health system’s domestic medical manufacturing and their service capabilities by comparing the results of the study to traditional standards of care. The Center of Disease Control’s National Center for Chronic Disease Prevention and Health Promotion reports that the leading causes of death and disability amongst adults in the United States is caused by preventable illnesses stemming from chronic conditions. The 2020 U.S. census data reveals that 77.9% of the U.S. population, or 258.3 million people, are adults. Also, 60% of adults in America have at least one chronic condition, while 40% have at least two. In addition to examining the applications of 3D Printers in enhancing efficiency in rural healthcare services, this study also aims to investigate the potential economic benefits that can be yielded through their utilization. Specifically, the study will compare the costs of utilizing 3D Printers for orthopedic services to traditional care procedures across a patient's journey. By analyzing the costs of care across a patient's journey from transportation to their final follow-up appointment, researchers will be able to determine if 3D Printers are able to provide a more sustainable and affordable care process. The knowledge acquired from this study will ultimately inform healthcare professionals, policy designers and other stakeholders on the viability and potential benefits of incorporating 3D Printers to healthcare operations.

SIGNIFICANCE OF THE STUDY

The U.S. health system has a serious access problem when one synthesizes the observations above. Sixty-two million risk adverse Americans are aging while having access to only 1% of total ICU beds. Triple aim rural healthcare systems who aspire to meet the demands of their communities must prioritize promoting efficiency in their operations; 3D Printers are a potential venture to efficiently meet that demand. This proposal asserts that by incorporating 3D Printers and its supplementary imaging software to the production of its corresponding medical supplies and services, such as casts and braces for orthopedic trauma, organizations can further improve access and efficiency regarding the treatment of orthopedic trauma in rural health systems. Numerous studies have already incorporated 3D Printers to orthopedic services and these studies show promising signs of reducing burden on both clinicians and inventory in a clinically viable timeframe [20].

CONCEPTUAL FRAMEWORK

If Portable X Ray Machines are used in the diagnosis of orthopedic fractures in rural health systems, and 3D Printers are used to manufacture casts during long distance patient transportation, then the availability of beds in rural health systems will increase. With respect to Triple Aim, this proposal hypothesizes that bed availability will increase, and clinician burden will be reduced for two reasons. The first reason being that negative x-ray results will reduce the quantity of patient transportation, admissions and radiology orders utilized. Less services utilized for negative testing of patients will ultimately save an organization time and money, while allowing healthcare personnel to focus on patients who require more pressing urgent care. Less patients in a health system will not only reduce clinician burden, but can also improve the outcomes of the remaining patients in the healthcare system, as well [20]. With this context, it is evident how the research proposal respects Triple Aim’s mission of reducing costs. while improving both the outcomes and experiences of those involved in the study. Patients get more time and attention from healthcare providers, while the providers themselves can better manage their patients with a smaller patient volume. The second reason being the other side of the spectrum, those who are confirmed to have an orthopedic fracture from an x-ray, can have both their x-ray assessed and cast constructed during patient transportation. This is done by sending two files ahead of the patient’s arrival. The first being the patients x-ray results and the second being a 3D printer file that contains a 3D replica of the injury site constructed using structured light technology [21]. This 3D replica of the injury site, a simple broken arm for example, is used in 3D printing software as a digital mold to build the cast around. By the time the patient arrives at the hospital and is admitted, the patient can immediately get their bone reset because the x-ray has already been taken and reviewed by a physician. As discussed in the Data Collection and Measures Section, a workflow analysis denoting time will be constructed for both the experimental group receiving the 3D printed casts and the control group receiving the traditional standard of care. Results will be compared by time, outcomes, complications, and cost.

LIMITATION OF THE STUDY

As a quasi-experimental study that looks at the outcomes of two different methods of treating simple orthopedic fractures, there are a few considerations that need to be addressed. As discussed in the Proposed Study Design Section, study participants will be voluntary, decide which group they will be part of, and will not be blinded. This is due to ethical considerations and the feasibility of the study. It is impractical to blind subjects for a period of months to prevent them from knowing the type of cast they receive. The casts are fundamentally different, and participants will easily be able to tell them apart; subjects will therefore realize which group they are a part of. It is important to mention that knowing which group participants are a part of might influence their answers in their VAS and exiting surveys.

Participation in the study will be naturally occurring, as researchers will have to wait for injuries to occur before asking for participation. The research team expects to have a limited sample size of participants, and of those participants, there will be a natural variation regarding the severity and site of injury. To mitigate this issue, the length of the proposed study will be 18 months to ensure a large enough sample size can be attained for statistical comparison; and an independent t-test will be used for statistical analysis, as it is optimal for sample sizes under 30. Due to the natural variation in injury severity and site, it is also important to limit study participants to simple orthopedic fractures. Severe complex fractures may require surgery, and potentially would only be eligible for traditional plaster casts. Because of this limitation selection bias is present, as eligible participants will only be those with simple orthopedic fractures. The combination of voluntary participation and limiting eligible candidates increases selection bias. This might weaken the validity and generalizability of the study results, as it might not represent the entirety of rural populations.

RESEARCH DESIGN AND METHODS

In essence, the following is a Feasibility Research Proposal to investigate the viability of 3D Printers and Portable X-Ray Machines in meeting the demands and gaps of rural health systems. By utilizing 3D printers, the research team plans to investigate the new technology’s flexibility and applicability to healthcare with respect to access and the objectives of Triple Aim. The population understudy will be rural patients who utilize the Portable X Ray Machines; with a focus on the elderly.

The Objectives of this Research Proposal are as follows:

- Investigate the impact of providing portable X-Ray machines to rural communities; specifically, Rural Emergency and Radiology Departments.

- Increase access to examinations and hospital beds by reducing the number of transfers from nursing homes and or clinics to the main hospital.

- Compare the study trial group to a control group that represents traditional orthopedic procedures by:

- Triple Aim

- Outcomes

- Time

PRELIMINARY DATA

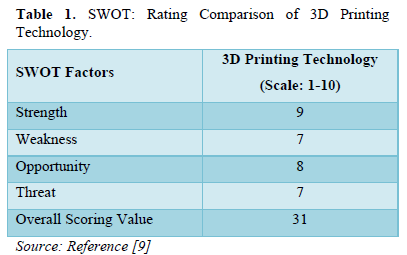

A SWOT Analysis can best be described as a situational analysis that assesses an organization's internal strengths and weaknesses, in juxtaposition to its external threats and opportunities within an industry [11] (Table 1). From a macro perspective, previous SWOT analyses of 3D printing technologies have scored highly in all four categories:

Universities from around the world collaborated and published their SWOT outlook of the 3D printing industry. As seen in Table 1, researchers agree that even though 3D printing scored relatively high in all four categories, the strengths and opportunities of 3D printing outweigh its weaknesses and threats. Located in the Findings and Analysis Section is a series of data sets that show promising signs on the applications of 3D Printers to treat orthopedic fractures. It compares the costs and outcomes of a control group that uses traditional standards of care to an experimental group that uses 3D Printed casts. An independent sample T- test is used to compare the average outcomes and costs of each group in the study. In doing so, researchers have the opportunity to see the degree of precision, or variability of each group and compare their means. This data analytical technique will be used in this research proposal and is discussed in further detail in the section below.

DATA ANALYSIS TECHNIQUES

In addition to patient perception surveys and a time-based workflow analysis, the study will compare all the measures identified above through an independent sample t-test. As mentioned briefly in the Preliminary Data Section, an independent samples t-test is a statistical method that researchers use to compare the average outcomes and costs of the experimental and control groups in a study. In utilizing this method, one can determine the level of variability between the averages of the two groups of measures. By comparing the averages of the two groups on measures, such as complications, patient perceptions, and time in healthcare system, researchers will be able to determine which aspects of each care process are most effective. Comparing the experimental and control group based on averages is preferable, due to the natural variability that will occur during the experiment, such as environmental factors, biological factors such as genetics, the severity of the injury, and its location.

PROPOSED STUDY DESIGN

Being a feasibility study that compares the effectiveness of a new procedure to that of a normal standard of care, this research proposal, in essence, is a quasi-experimental study that will follow patients over time, as their bones heal. For rightful ethical reasons, researchers will be evaluating orthopedic fractures that differ in severity and location, as they become part of the study. Injuries will naturally differ between subjects in both the control and study groups as researchers are not allowed to cause harm to participants. Due to the fact researchers are observing orthopedic fractures and their outcomes as they arise, each participant in the study group will have their outcomes evaluated to patients who have experienced similar injuries; specifically, simple orthopedic fractures. Spanning for the duration of a year, prospective, eligible subjects will be asked if they would like to voluntarily participate in the study. Experimental clinical studies often have high levels of ethical risk and informed consent will therefore be required for participation. Due to the fact that the materials and processes used in traditional, and 3D printed casts are different, blinding subjects and researchers for the months and weeks it takes for a fracture to heal is unrealistic. Therefore, eligible candidates will have the opportunity to select which group they will be part of. From the patient's perspective, the only difference between the control and study groups will be:

- Where they receive their X-Ray:

- Control: (Standard of Care Practice) At Emergency Department after transportation and admission

- Experimental: On site at the nursing home (or clinic depending on sponsor)

- The type of cast they will receive:

- Control: Traditional Plaster Cast

- Experimental: 3D Printed Cast

*Note that where subjects decide to get their X-Ray and which type of cast they receive will not have an impact on their care plan after being discharged.

FINDING AND ANALYSIS

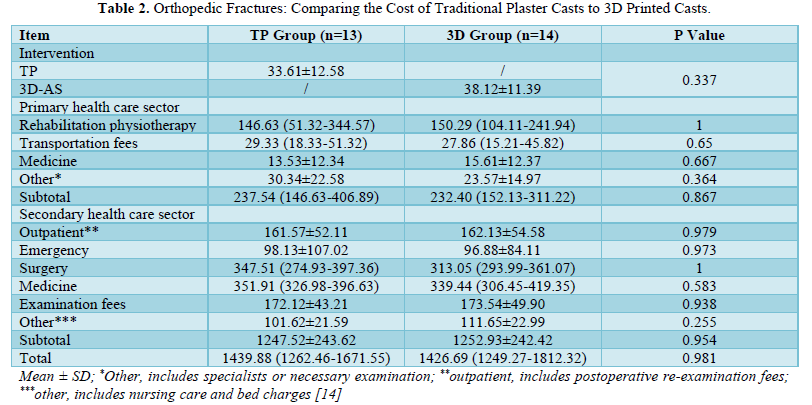

A t-test that compares the overall costs of each group's utilization suggests that 3D Printed casts can feasibly be delivered at relatively the same cost as standardized plaster casts [14] (Table 2). The large p values indicate no statistical differences regarding costs between traditional plaster casts and 3D printed casts (3D-AS) across the average patient's journey; from the intervention to their final follow-up appointment:

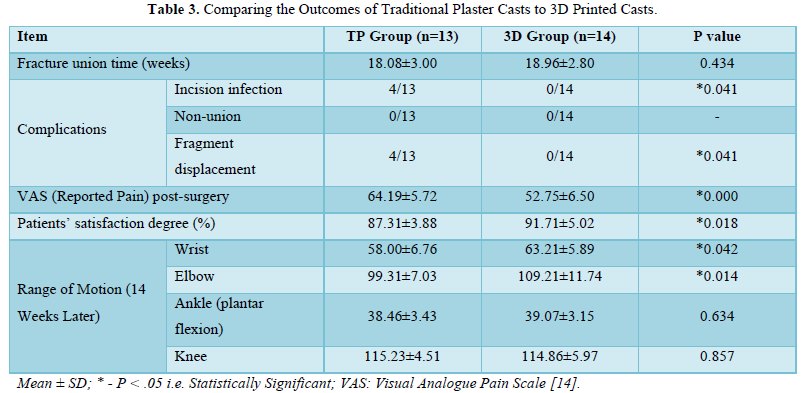

When conducting a t-test by outcomes of the two groups, it is important to note that no statistical differences were found regarding overall healing time [14]. However, statistical differences were identified regarding complications, reported pain (VAS) post-surgery, patient satisfaction, and range of motion (ROM) 14 months after discharge [14] (Table 3). In these categories, the experimental (3D) group was found to be a more successful and favorable journey than that of the traditional standard of care (TP) control group across every metric; this can be seen below by the corresponding bolded P Values below a value of .05:

The data in Table Two further supports this research proposal's hypothesis that 3D Printers can be feasibly incorporated into the treatment of orthopedic fractures in healthcare systems. Vital to the analysis of this research proposal is an evaluation of the impact of the experimental group's independent variables with respect to triple aim’s objectives. The experimental group above for example, reported less pain post-surgery and feeling more satisfied at the end of their journey. This suggests 3D Printed casts are more effective at improving the patient’s experience than traditional plaster casts. Table 2’s data on Complications and ROM also indicate that 3D Printed casts are less risky and improve the health of the population more effectively than traditional plaster casts. As seen in Table One, these improvements to the orthopedic fracture care procedures can all be achieved without placing additional costs on the patient or organization. Findings from other observational studies such as Leyi [22] concluded that there was no significant difference between two groups in respect to general conditions, such as age, gender, fracture type, time from injury to operation, injury cause, and combined injury. About one hundred thirty-seven patients with unstable pelvic fracture’s studies, between 2014 to 2016, based on the usage of 3D printing technology for preoperative simulation surgery analyzed were included in the studies. These two groups were assigned to 3D printing group (n=65) and control group (n = 72). The group were then assessed in terms of operative time, intraoperative fluoroscopy, postoperative reduction effect, fracture healing time, and follow-up function. The effect of 3D printing technology was evaluated through minimally invasive cannulated screw treatment. Another study used methods that can shorten the preoperative preparation time significantly by analyzing two groups with the same 21 patients, who underwent surgery for traumatic anterior pelvic ring fractures. In Group 1, the direct reconstruction plates were preoperatively contoured according to the anatomical 3D-printed pelvic model. In Group 2, the fixation plates were contoured according to the 3D printed plate templates, which were created based on the simulated plate templates by the OOOPDS software. The processing time, including the 3D printing time for the pelvic models in Group 1, the 3D printing time for the fixation plate templates in Group 2, and the pre-contouring time for the plates in both groups, was recorded. The result shows the mean time of pre-contouring for the curved reconstruction plates in Group 2 was significantly less than in Group 1 (-55 min; P < 0.01). The mean time of 3D printing for the 3D plate template model in Group 2 was significantly less than that for the 3D pelvic model in Group 1 (-869 min; P < 0.01). Experimental results showed that the printing time for the plate pre-contouring and the 3D plate templates could be effectively reduced by approximately 93% and 90%, respectively [23]. A review of twenty articles by Assink, et.al. (2021) evaluated 948 patients treated with 3D-assisted surgery and 126 patients with conventional surgery were included. Five different concepts of 3D-assisted surgery were identified: '3D virtual visualization', '3D printed hand-held fracture models', 'Pre-contouring of osteosynthesis plates', '3D printed surgical guides', and 'Intra-operative 3D imaging'. 3D-assisted surgery resulted in reduced operation time (104.7 vs. 126.4 min; P < 0.01), less blood loss (241 ml vs. 306 ml; P < 0.01), decreased frequency of fluoroscopy (5.8 vs. 9.1 times; P < 0.01). No differences in functional outcome was found (Hospital for Special Surgery Knee-Rating Scale: 88.6 vs. 82.8; P = 0.23). This result proved that 3D-assisted surgery may have a positive effect on operation time, blood loss, and fluoroscopy frequency. Finally, Seung [24] reported their experience of preoperative plate contouring for periarticular fractures using three-dimensional printing (3DP) technology and describe its benefits by enrolling 34 patients, including 11 with humerus midshaft fractures, 12 with tibia plateau fractures, 2 with pilon fractures, and 9 with acetabulum fractures. The entire process of plate contouring over the 3DP model was videotaped and retrospectively analyzed. The total time and number of trials for the intraoperative positioning of precontoured plates and any further intraoperative contouring events were prospectively recorded. The mismatch between the planned and postoperative plate positions was evaluated. The average plate contouring time was 9.2 min for humerus shaft, 13.8 min for tibia plateau fractures, 8.8 min for pilon fractures, and 11.6 min for acetabular fractures. Most precontoured plates (88%, 30/34) could sit on the planned position without mismatch. In addition, only one patient with humerus shaft fracture required additional intraoperative contouring. Preoperative patient specific periarticular plate contouring using a 3DP model is a simple and efficient method that may alleviate the surgical challenges involved in plate contouring and positioning.

CONCLUSION AND RECOMMENDATIONS

This research proposal aims to study the impact of utilizing 3D Printers in the manufacturing process of casts for orthopedic fractures. If the proposal is successful, and the hypothesis is proven to be true, the study could have significant impacts on future research and clinical outcomes regarding the field of orthopedics and fractures. The use of 3D Printers and portable medical equipment additionally has the potential to revolutionize care in rural communities. The portability and flexibility of the equipment in the proposal has the potential to reduce the cost of delivering care by making it more efficient. Patient transportation can be reduced and free up bed access through negative test results identified at rural locations. Those who do require transportation can have their casts manufactured during transportation to get them out of the healthcare system faster. If the research proposal proves to be beneficial for the healthcare system based on outcomes and Triple Aim in a time efficient manner, the continual study of this technology and procedure could lead to widespread adoption and innovation in the healthcare industry beyond the field of orthopedics. During their final appointment, participants were asked to take a patient satisfaction survey asks patients a series of questions regarding their experiences during their care process, their perceptions on the quality of care they received, and their outcome. To be able to compare answers, the study itself asks patients to circle their answer via a numerical scale, 1-5, denoted as Very Dissatisfied to Very Satisfied. The mean of each answer of both groups can then be compared to see which aspects of their care process are preferred by the community. The survey helps researchers attain data that help them accomplish the proposals third objective with respect to Triple Aim’s theme of prioritizing the patients experience and identifying how their outcomes and time in the hospital influenced their perceptions. Additionally, to evaluate the overall feasibility of the procedure under study, the experimental procedure will be compared to the traditional standard of care process via a workflow analysis that denotes time at each stage. Time is crucial for a feasibility study to evaluate if the new process, or at least part of it, can be performed in a realistic, permissible timeframe. By comparing time spent at each stage of the care process of both groups, researchers will be able to identify the components of the care process that are most efficient, identify the stages where adverse events arise, and generate opportunities for improvement during the analysis phase of the study [25]. Additionally, researchers will be able to see differences between groups, such as the number and types of staff members involved, the resources consumed, and the location of where these resources and staff members are utilized. The Workflow Analysis of the study directly addresses the first two objectives of the research proposal. By providing rural senior living organizations and or clinics with Portable X Ray Machines and conducting a workflow analysis, researchers will be able to measure how much time and resources are saved when negative X Ray results bar the need of patient transportation and ED admission. The time, costs and impact on bed access can all be extrapolated from a workflow analysis through the observations made from each patient's journey. Lastly, it will be important to monitor and record the number and types of complications that arise amongst study participants. In doing so, the study analyzes results by outcomes; if one group has more complications than another, it will suggest the alternative care process is more effective than the other. Complications that could arise include infections and improper bone graphing.

- Dall T (2019) The complexities of physician supply and demand: Projections from 2019 to 2034. AAMC. Available online at: https://www.aamc.org/data-reports/workforce/data/complexities-physician-supply-and-demand-projections-2019-2034

- Davoodi NM, Healy M, Goldberg EM (2020) Rural America's hospitals are not prepared to protect older adults from a surge in COVID-19 cases. Gerontol Geriatr Med 6: 2333721420936168.

- Center for Drug Evaluation and Research (2019a) Safeguarding pharmaceutical supply chains in a global economy. U.S. Food and Drug Administration. Available online at: https://www.fda.gov/news-events/congressional-testimony/safeguarding-pharmaceutical-supply-chains-global-economy-10302019#:~:text=As%20of%20August%202019%2C%20only,13% 20percent%20 are%20in%20China

- Office of the Commissioner (2022) Advanced manufacturing. U.S. Food and Drug Administration. Available online at: https://www.fda.gov/emergency-preparedness-and-response/mcm-issues/advanced-manufacturing

- Food and Drug Administration (2021) Drug shortages for calendar year 2021 - Food and Drug Administration. Food and Drug Administration. Available online at: https://www.fda.gov/media/159302/download

- University of Oklahoma. (n.d.). Diffusion of Innovation Theory. The University of Oklahoma. Available online at: https://www.ou.edu/deptcomm/dodjcc/groups/99A2/theories.htm

- Garber J (2020) What worries you most? Survey examines patients' biggest health care Lown Institute. Available online at: https://lowninstitute.org/what-worriess-you-most-survey-examines-patients-biggest-health-care-worries

- American College of Healthcare Executives (2022) Top issues confronting hospitals in 2021. American College of Healthcare Executives. Available online at: https://www.ache.org/learning-center/research/about-the-field/top-issues-confronting-hospitals/top-issues-confronting-hospitals-in-2021

- Quanjin M, Idris MRM, Kumar NM, Abdullah MH, Reddy GR (2020) Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput Sci 167: 1210-1219.

- Thomas G (2020) Rural development project uses 3D printing in fight against COVID-19 spread. USDA Rural Development, National Science Foundation. Available online at: https://www.rd.usda.gov/newsroom/success-stories/rural-development-project-uses-3d-printing-fight-against-covid-19-spread

- Martin BC (2019) Chapter 2. In strategic planning in healthcare; essay, Springer Publishing Company. pp: 20-36.

- University of Southern California (2023) Research guides: Organizing your social sciences research aper: Narrowing a topic idea. Narrowing a Topic Idea - Organizing Your Social Sciences Research Paper - Research Guides at University of Southern California. Available online at: https://libguides.usc.edu/writingguide/narrowtopic

- National Science Foundation (2023) Chapter II: Proposal preparation instructions. NSF. Available online at: https://beta.nsf.gov/policies/pappg/23-1/ch-2-proposal-preparation

- Chen L, Xiong Y, Mi B, Yan C, Xie X, et al. (2021) A novel instant 3-dimensional printing system for postoperative fracture patients: A comparative cohort study. Med Sci Monit 27: e928240-e928240.

- Smith A, Trevelyan E (2021) In some states, more than half of older residents live in rural areas. Census.gov. Available online at: https://www.census.gov/library/stories/2019/10/older-population-in-rural-america.html

- Pendall R, Goodman L, Zhu J, Gold A (2016) The future of rural housing. Urban Institute. Available online at: https://www.urban.org/research/publication/future-rural-housing#:~:text=The%20housing%20needs%20of%20rural,pass%20age%2060%2C%20salaries%20decline

- RHIhub (2023) Rural health disparities. Rural Health Information Hub. Available online at: https://www.ruralhealthinfo.org/topics/rural-health-disparities

- Zwerling C, Peek AC, Whitten PS, Choi SW, Sprince NL, et al. (2005) Fatal motor vehicle crashes in rural and urban areas: Decomposing rates into contributing factors. Inj Prev 11(1): 24-28.

- Factor S, Atlan F, Pritsch T, Rumack N, Golden E, et al. (2022) In-hospital production of 3D-printed casts for non-displaced wrist and hand fractures. SICOT J 8: 20.

- Cimiotti JP, Aiken LH, Sloane DM, Wu ES (2012) Nurse staffing, burnout, and health care-associated infection. Am J Infect Control 40(6): 486-490.

- Artec Europe (2023) 3D object scanner ARTEC EVA: Best structured-light 3D scanning device. Professional 3D scanning solutions |Artec 3D. Available online at: https://www.artec3d.com/portable-3d-scanners/artec-eva?utm_source=google&utm_medium=cpc&utm_campaign=1937302799&utm_term=%2Bartec+%2Beva+%2Bscanner%7C%7Ckwd332971544296&utm_content=76342286371%7C%7C&keyword=%2Bartec+%2Beva+%2Bscanner&gad=1&gclid=CjwKCAjw9J2iBhBPEiwAErwpeXmDX_FrVo2fgQtM0s7kR_AGvoLgCa4WbzfhwNXUPjnIYVwedMTsKBoCzhkQAvD_BwE

- Leyi C, Yingying Z, Chunhui C, Yiting L, Xiaoshan G, et al. (2018) 3D printing-based minimally invasive cannulated screw treatment of unstable pelvic fracture. J Orthop Surg Res 13(1): 71.

- Xu SS-D, Yeh T-T, Chen J-E, Li Y-T (2023) Significantly reducing the presurgical preparation time for anterior pelvic fracture surgery by faster creating patient-specific curved plates. J Orthop Surg Res 18(1): 265.

- Sakong S-Y, Cho J-W, Kim B-S, Park S-J, Lim E-J, et al. (2023) The clinical efficacy of contouring periarticular plates on a 3D printed bone model. J Pers Med 13(7): 1145.

- Vankipuram M, Kahol K, Cohen T, Patel VL (2010) Toward automated workflow analysis and visualization in clinical environments. J Biomed Inform 44(3): 432-440.

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Infectious Diseases and Research (ISSN: 2688-6537)

- International Journal of Diabetes (ISSN: 2644-3031)

- International Journal of Radiography Imaging & Radiation Therapy (ISSN:2642-0392)

- Journal of Carcinogenesis and Mutagenesis Research (ISSN: 2643-0541)

- International Journal of Medical and Clinical Imaging (ISSN:2573-1084)

- Advance Research on Alzheimers and Parkinsons Disease

- Journal of Neurosurgery Imaging and Techniques (ISSN:2473-1943)